| Sign In | Join Free | My spintoband.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My spintoband.com |

|

Brand Name : Sunda

Model Number : SD-20HMV-4X

Certification : ISO,CE

Place of Origin : China

MOQ : 1

Price : SD-20HMV-4X

Payment Terms : L/C,D/A,D/P,T/T,Western Union

Supply Ability : 5pcs/month

Delivery Time : 15days

Products Desription:

IndustrialMicrowave drying equipment is very different from traditional drying equipment. Microwave drying is a microwave frequency of 300 MHz to 300 MHz. Water molecule in heated medium material is polar molecule. Under the fast changing high frequency electromagnetic field, its polar orientation will change with the change of external electric field. At this time, the field energy of the microwave field can be converted into the heat energy in the medium, so that the material temperature rises, and aseries of physical and chemical processes such as heating and expansion are produced to achieve the purpose of microwave heating and drying.

Microwave dryer is more and more popular nowadays.Microwave energy is converted into direct effects on heat.Microwave has penetrating performance inside and outside the media heating at the same time. Microwave can saving drying time and aviod the raw material becoming metamorphism or coking the overheat environment,The drying effect is good for seafood,tea,pandan leaf herb and so on.

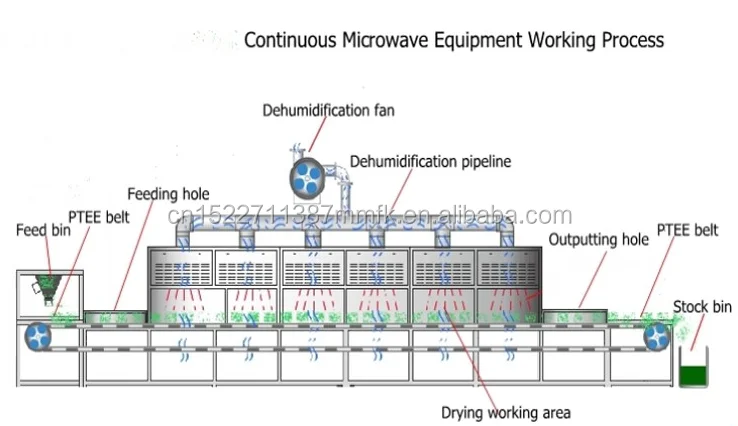

The structure of microwave drying machine food dehydrator sterilizer

1. feeding system

2.microwave cuppersion system

3.dehumidifcation system

4.elecronic controll system

5.microwave drying boxes

6.transmission system

7.Discharge system

The advantages and functions

1)High efficiency.

As the industrial microwave dryer can be absorbed easy by the materials which contain moisture, there is very few wave wasting. Compare with the traditional ultrared rays heating ways, it will save at least 30%.

2) Keeping fresh.

The Sterilization is with lower temp, so the nutritions inside the food can be protected well.

3) Easy to control.

The microwave can be controlled easily. So it can be used to dry the food continuously to save labor.

4) Energy saving

The material containing is easy to absorb microwave heat, therefore, there is no other heat loss besides a small amount of transmission loss. So higher thermal efficiency and more energy saving, which is heating energy-saving1/3 over than the far infrared heating.

Advantages of microwave food sterilizer, food dehydrator, fruit drying machine

1. PLC automatically system control.

2. Camera inspection immediately check with material condition.

3. A wide range of feeding solution including hopper feeding, vibration feeding, shaking feeding and liquid dripping feeding.

4. Flexible control microwave heating temperature, belt running speed and power output.

5. It apply for sterilizing, drying, heating, sintering, curing, cooking and vulcanizing etc.

Application flieds

itis widely used to drying and sterilizing of leaf, powder,granular, sheet-like or gel-like food ,and additive, flavoring, medicine, raw material of herbal medicine, nutritional health products, agriculture & sideline products non-fried(or oil-saving) and soon on.

|

|

New tunnel type microwave equipment carbon microwave sterilization drying machine Images |